Manufacturing co. production store automation with Kardex Storage System & Oracle eBiz ERP Interface Software Success story

Case Study of Automation of production stores and improvement in efficiency of stores.

Overview: Our client is India’s largest gear manufacturer company who offers broad range of and large sized gears used in manufacturing, shipping, and power industries. The client was using Oracle eBusiness Suite ERP for managing the operation all of business units. They procured an automatic (electronic) storage system (shuttle) from an Electronic Storage Manufacturing company from Germany. The storage systems was having vertical tray system with microprocessor based control system to manage material storage and retrieval operations.

Challenges

- Using Oracle eBusiness Suite ERP for managing multiple operations like sales, manufacturing, inventory, production, stores, dispatch etc.

- The electronic storage system has separate microprocessor-based control panel which manages the tray movement.

- For managing inventory in electronic storage shuttle, they had to enter the storage location, tray number manually on panel and stock in storage was managed manually. Lot of time was spent in finding proper item for delivery to production floor.

- Biggest challenge was discrepancy in inventory in ERP and actual physical quantity in hand, which leads to confusion and delay in delivery of raw material to production, so delay in shipping of sales orders resulting in loss of revenue.

- Facing huge productivity loss and problems in reconciling the inventory levels.

- Duplicate storage locations were created for same item and also, similar types of items were kept at different locations as it was difficult to manage while storing items in storage shuttle. There were 30 storage systems / shuttles in the factory. There were a huge number of items stored in systems.

Solutions

- We analyzed the issues and designed software solution for it.

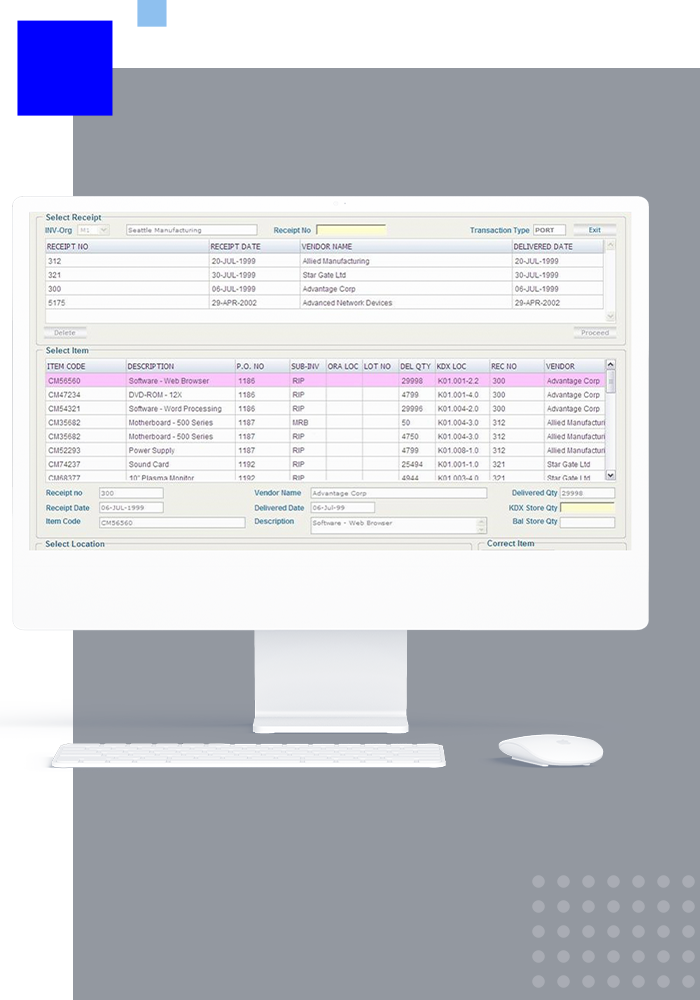

- To solve the inventory mismatch issue, we stopped the duplicate entry in Oracle ERP and on Storage Control panel. We developed and implemented interface software which was accepting all the user inputs and we operated the storage unit by sending instructions to microprocessor. We developed API interface to Oracle ERP so direct entry was passed to ERP.

- Operators were standing in front of automatic storage systems and trays were coming out automatically one after another, operator was required to make single entry of items selected and picked/placed.

- Transactions were done only once in an interface software and both the systems were automatically updated.

- We observed the operator movements and improvised the software by which one operator was able to manage two shuttles (leftside and rightside) with the help of a labor, so the manpower requirement and cost was reduced.

- Further we developed algorithm for storing the similar type of items in the same tray and all duplicate tray /bin locations were removed.

Results

- Real time interface between both systems storage controller and Oracle eBusiness Suite ERP applications.

- Eliminated duplicate transaction entry resulting to increase in productivity

- Less manpower for performing operations.

- Eliminated inventory synchronization for both the systems.

- Reduction in cost due all the customized development.

- Stores efficiency for material receiving and issuing was improved by 40%.