Table of Contents

ToggleIn industries such as shipbuilding, construction, manufacturing, and facility maintenance, coordinating maintenance tasks from routine repairs to large-scale refits or new builds can quickly become overwhelming. Without a unified system, teams struggle with disjointed workflows, miscommunication, delays in procurement, lack of visibility, and compliance issues.

Yet, most enterprises still rely on spreadsheets, emails, siloed tools, paper-based logs, and unstructured work instructions. This leads to inefficiencies, delays, mismatched procurement, miscommunication, and compliance gaps.

To solve this, Netwin’s software product engineering team designed a unified industrial maintenance software platform that centralizes maintenance planning, procurement, asset mapping, documentation, and collaboration, giving decision-makers complete operational visibility.

This blog presents a real case study of how a multi-industry enterprise adopted this solution to drive efficiency, traceability, and cost control.

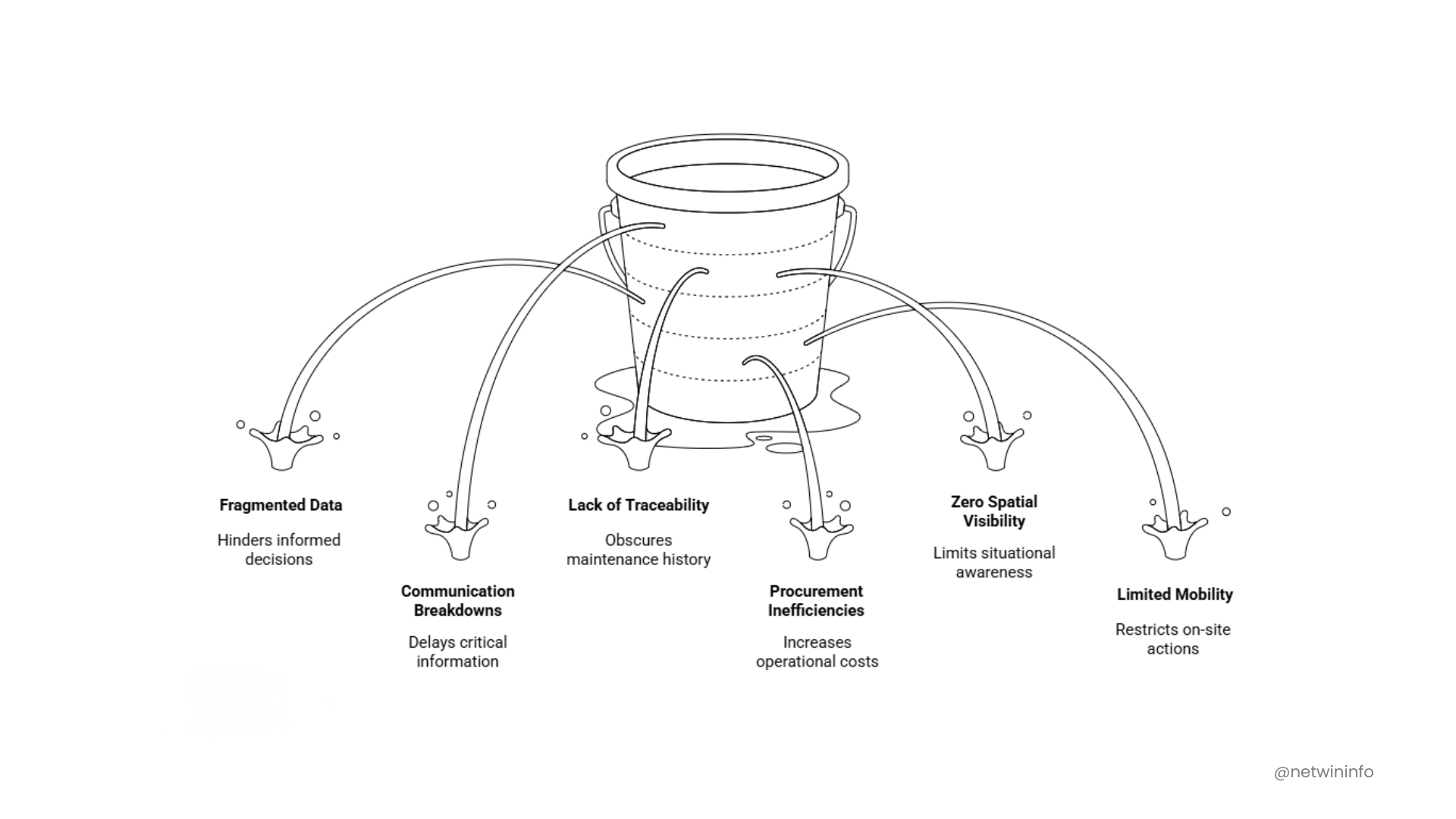

The Problem: High Complexity, Low Visibility

Before using the platform, the organization faced a familiar set of challenges seen across maintenance-heavy companies:

Fragmented Data & Disconnected Workflows

Teams used different tools to track work lists, long-term projects, spare parts, purchases, and inspections, none of which talked to each other.

Communication Breakdowns

Project managers, contractors, surveyors, and in-house technicians often lacked real-time updates. Tasks were missed, duplicated, or delayed.

Lack of Traceability

There was no unified history of: what was repaired, who completed it, which part was used, or how costs changed over time. This created bottlenecks in compliance, audits, and safety reviews.

Procurement Inefficiencies

Incorrect part identification, missing technical specs, and manual entries often led to wrong orders or expensive returns.

Zero Spatial Visibility

For assets like ships, heavy machinery, or large facilities, tasks were not mapped onto layouts. Teams lacked location context, causing delays and confusion.

Limited Mobility for On-Site Teams

Technicians working remotely, offshore, or on shop floors couldn’t access or update tasks on the go.

The result?

Cost overruns, slow decision-making, compliance gaps, and inconsistent maintenance outcomes.

The Solution: A Fully Integrated Industrial Maintenance Software Platform

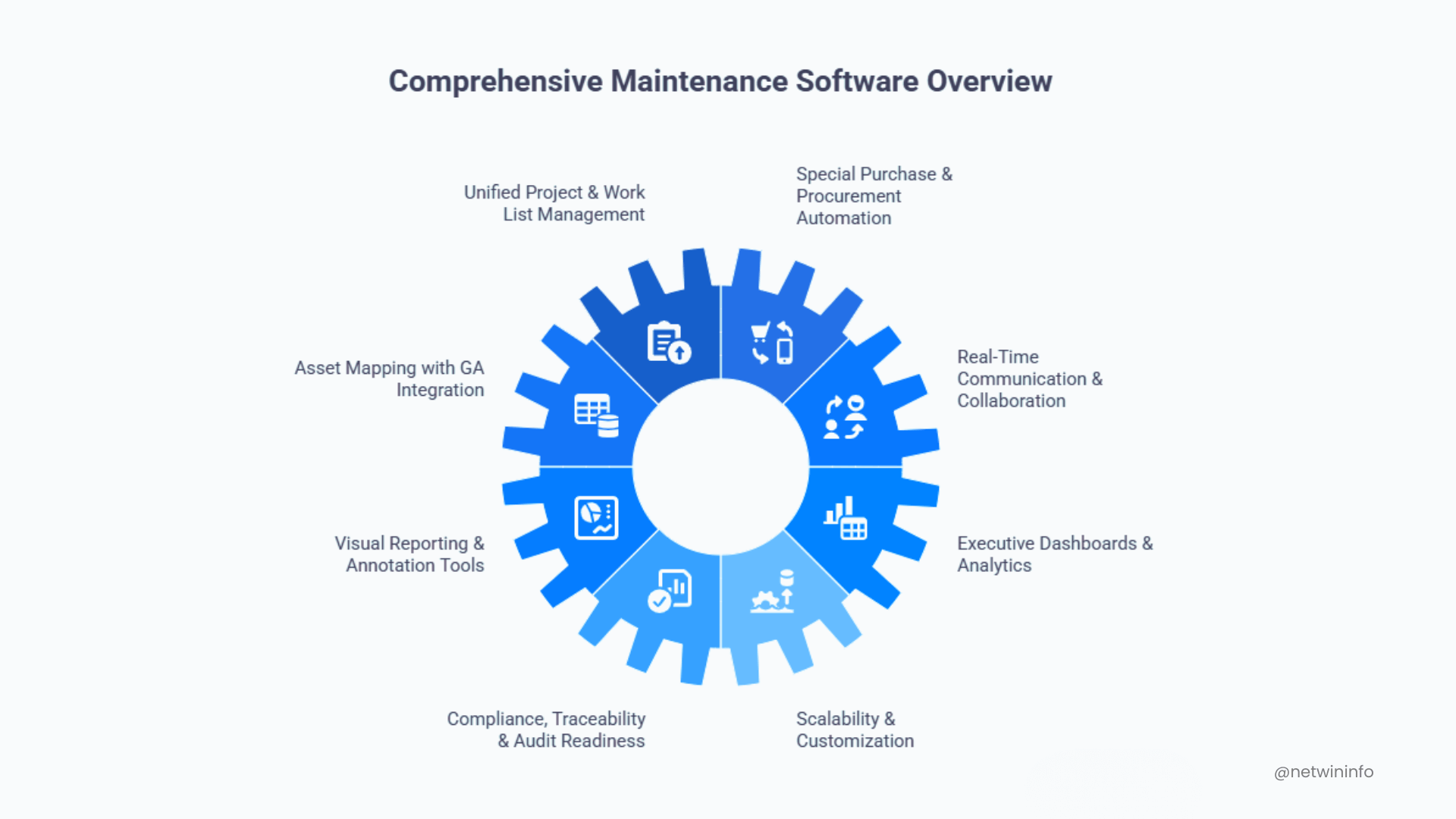

To unify workflows, strengthen asset governance, and modernize operations, the organization deployed a comprehensive industrial maintenance platform. The platform integrates all critical maintenance and procurement processes into one intelligent ecosystem.

1. Unified Project & Work List Management

Most maintenance operations fail because projects and day-to-day tasks run on separate, disconnected systems. Netwin’s product engineering team structured the platform to separate long-term project cycles from day-to-day work lists, giving decision-makers both high-level oversight and granular control.

We engineered dual-layer task architecture for project lists & work lists. Built interconnected workflows linking tasks, assets, procurement, and documentation. Enabled dynamic progress tracking, dependencies, and approvals.

Now, the system:

- Manages long-term project plans

- Manages daily work lists (repairs, inspections, emergency tasks, safety checks).

- Tracks approvals, deadlines, dependencies, responsible teams, and progress updates.

- Links tasks to asset components, locations, drawings, or purchase items.

Decision-makers can now view everything, from big-picture project progress to the smallest task detail without switching between tools or chasing teams for updates.

2. Special Purchase & Procurement Automation

Procurement is often the largest source of delays and errors. Our automated procurement engine was integrated to ensure accuracy and speed across all purchase cycles.

- The system allows technicians to initiate purchase requests directly from tasks.

- Centralizes specifications, photos, part numbers, and vendor details.

- Includes OCR (Optical Character Recognition) to read serial numbers from photos, reducing manual errors.

- Tracks quotes, vendor selection, approvals, purchase orders, and delivery status.

- Automatically links purchased parts back to the maintenance task for audit traceability.

Now, the procurement no longer depends on guesswork or memory. Every detail is captured, every request is standardized, and every purchase is tracked.

3. Asset Mapping with GA (General Arrangement) Integration

Netwin introduced an interactive General Arrangement (GA) module to give leaders geographical insight into task distribution across ships, plants, facilities, or large equipment layouts.

- The unified platform lets users upload GA plans, blueprints, or layout diagrams of ships, buildings, plants, or factories.

- Enables teams to pin maintenance tasks directly onto the layout.

- Supports multiple views: deck-wise, floor-wise, section-wise, or component-wise.

- Allows users to annotate diagrams with photos, comments, and additional notes.

This elevated the entire maintenance process by transforming static plans into living, actionable intelligence.

4. Real-Time Communication & Collaboration

Maintenance involves coordination between internal teams, external contractors, vendors, and safety inspectors. Miscommunication can create major delays and safety risks. We integrated a collaboration system built for enterprise-scale communication. This ensured that every stakeholder, internal or external, works in sync, accelerating work execution and reducing friction.

- The System enables live task updates with timestamps, comments, attachments, and approvals.

- Tracks conversations between technicians, engineers, contractors, and managers, all in one place.

- Sends automated reminders and deadline alerts.

- Allows contractors to access only the tasks assigned to them (controlled permissions).

- Keeps all communication tied to the task, eliminating long email trails.

5. Visual Reporting & Annotation Tools

In maintenance, a picture is more powerful than a paragraph. It reduces ambiguity, confirms the extent of a problem, and provides clear evidence for audits.

The system now:

- Allows uploading photos, videos, sketches, and annotated images.

- Supports before/after comparison.

- Enables marking specific damage areas or instructions visually.

- Generates structured visual reports for managers, auditors, and clients.

6. Executive Dashboards & Analytics

Maintenance generates immense amounts of data, but without structure, it’s useless. Leaders need actionable insights, not just raw numbers. We ensured that leadership teams get real-time visibility through powerful analytics and dashboards.

- The system offers high-level dashboards for executives and operational dashboards for managers.

- Tracks metrics such as:

- Task completion rates

- Delays and bottlenecks

- Procurement cycles and cost overruns

- Critical asset health

- Contractor performance

- Maintenance backlog

- Provides filters for asset type, project, date, location, team, or vendor.

- Supports export for board presentations, audits, and compliance reporting.

7. Compliance, Traceability & Audit Readiness

Maintenance-heavy sectors must maintain stringent records for safety, environmental, and regulatory compliance. Netwin’s unified maintenance management system helped teams stay compliant without extra administrative effort. Auditors get clarity instantly.

- Logs every action with timestamps and user identity.

- Keeps historical records of tasks, parts used, images, inspections, and approvals.

- Generates audit-ready reports with a single click.

- Maintains complete traceability from problem identification to closure.

8. Scalability & Customization

Netwin’s modular architecture ensures the platform adapts to diverse industries, asset types, and operational scales.

- Supports modular adoption, that means teams can start small and scale.

- Allows custom fields, workflows, templates, and automation rules.

- Integrates with existing enterprise systems without disrupting operations.

- Serves multi-location, multi-department, multi-vendor environments seamlessly.

Key Takeaways

- Centralization Changes Everything: A single platform replaces fragmented tools, improving oversight and reducing operational risk.

- Data-Backed Decisions Are the Future: Dashboards and real-time updates allow leaders to plan proactively, not reactively.

- Mobility Matters: Maintenance doesn’t happen at desks. Your software shouldn’t be desk-bound either.

- Digital Procurement Prevents Loss: Automated, verified, and traceable procurement cuts costly mistakes.

- Visual Documentation Improves Accountability: Images, annotations, and mapped locations make maintenance transparent and auditable.

Conclusion

This case study shows how a modern industrial maintenance software platform can transform maintenance operations across industries.

By centralizing workflows, strengthening communication, enabling real-time updates, integrating procurement, and supporting mobile work environments, the solution helped the enterprise:

- Reduce operational complexity,

- Cut procurement errors,

- Improve reporting,

- Boost compliance,

- Accelerate maintenance cycles.

For businesses, the message is clear:

Investing in a unified maintenance platform is no longer optional, it is a strategic advantage.

If your organization handles large assets, complex maintenance cycles, or multi-team coordination, now is the time to explore a digital maintenance platform that gives you total visibility and control.

Netwin can help you modernize your operations with scalable, intelligent, and future-ready digital solutions.